Multi-axis CNC gantry drilling machine CJH6010M

Use of machine tool:

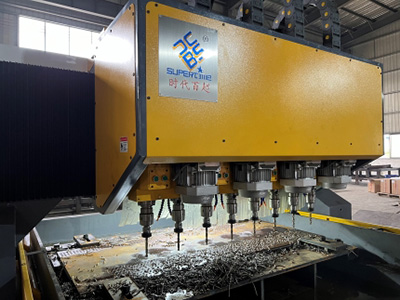

Multi-axis CNC gantry drilling machine is mainly used for drilling and tapping of regular and dense hole workpieces such as sieve plates, wear-resistant plates, optical platforms, etc. The multi-axis CNC drilling machine is a gantry moving drilling machine with a double gantry multi-spindle structure. The equipment is equipped with 16 spindles as standard, which can form 16 holes at a time and has high processing efficiency.

Features of machine tools:

1. The worktable and gantry are steel plate welded box structure, and the overall structure is stabilized by aging heat treatment; two ball guide rail pairs are installed on the front side of the gantry, and a transverse sliding saddle is installed; a ball screw pair is installed between the sliding saddle and the guide rail, which is driven by a servo motor to achieve Y-axis positioning.

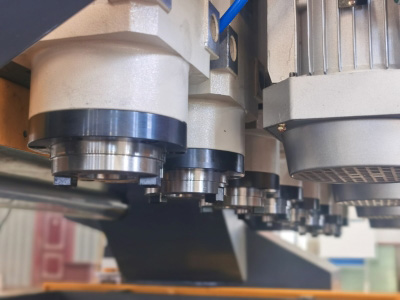

2. The multi-axis CNC gantry drilling machine adopts CNC sliding pillow power head (Z-axis). The stroke is pre-set according to the workpiece, which can realize the automatic conversion of the drill bit fast-forward-forward-forward. It has the advantages of high processing efficiency, simple structure and low maintenance cost. The spindle adopts BT40 rigid precision spindle, and carbide drills can be used for high accuracy. Equipped with a tool cylinder, it is extremely convenient to load and unload tools.

3. There are a total of 12 CNC axes in the multi-axis CNC gantry drilling machine: the movement of the gantry (2 x axes); the movement of the power head on the gantry beam (2 y-axis); the feed movement of the power head (8 z-axis). Each CNC shaft is guided by a precision linear rolling guide rail. The X axis is driven by a servo motor + reducer through a precision gear rack pair, and the Y and Z axes are driven by a servo motor + ball screw pair. Flexible movement and accurate positioning.

4. The numerical control system is controlled by a Guangzhou 988 numerical control system. The drilling coordinates can realize the direct conversion of CAD/CAM. It is equipped with USB interface, RS232 interface and LCD screen, which facilitates programming, storage, display and communication. The operation interface has inaccuracy error compensation, automatic alarm and other functions. It has the function of preview and re-examination of the hole before drilling, which is easy to operate.

Machine tool parameters:

| Parameters Name | Items | Values |

|---|---|---|

| Effective processing range | Length * Width | 6000×1600mm |

| Maximum height of the workpiece | 100mm | |

| Worktable | T-slot width | 22mm |

| Vertical ram-type power head | Number | 16 |

| Spindle taper hole | BT40 | |

| MAximum hole diameter | Φ18mm | |

| Spindle rotation speed | 1500r/min | |

| Spindle motor power | 3kW | |

| Spindle end to the work surface distance | By User | |

| Gantry longitudinal move (x axis) | Largest travel | 6000mm |

| Maximum distance between the main shafts of the two gantry | About 7m | |

| X axis movement speed | 0-10m/min | |

| X axis servo motor power | 2×2.8kW | |

| Power head lateral movement(Y axis) | Power head range | 1600mm |

| Y axis movement speed | 0-10m/min | |

| Y axis servo motor power | 2×2.8kW | |

| Vertical ram feed movement(Z axis) | Z axis stroke | 200mm |

| Z axis feed speed | 0-5m/min | |

| Z axis servo motor powe | 8×2.4kW | |

| Positioning accuracy | X axis | 0.06/2000 mm 0.12/whole length |

| Y axis | 0.04mm/whole length | |

| Re-positioning accuracy | X axis | 0.05mm |

| Y axis | 0.025mm | |

| Automatic lubrication system | Lubrication pressure | 2MPa |

| The amount of oil injection at the lubrication point | 0.1mL | |

| Lubrication cycle | 6-10min | |

| Electrical system | CNC system | Guangzhou 988 |

| CNC axes | 12 | |

| Total power | About 82kW | |

| Overall size | L×W×H | About 12×4.5×2.6m |