Hydraulic Angle Notching Machine QJZ

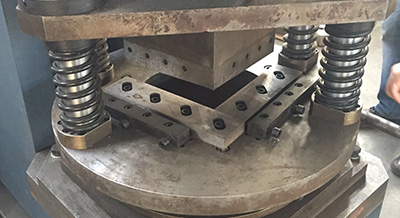

Machine application:

Machine is mainly used for angle notching or cutting, can equip with punching, marking, bending units, convenient mold change, easy operation.

Machine features:

1. Machine is C type frame, with stiffened plate, post welding stress relieving annealing acquires better rigidity and processing stability.

2. Notching mold after relieving annealing, with good wear resistance and rigidity.

3. Angle fixed, realizes angle notching of different angles by turning rotary worm.

4. Less land occupation and less error.

5. Can equip with punching, marking, bending units.

Parameter list:

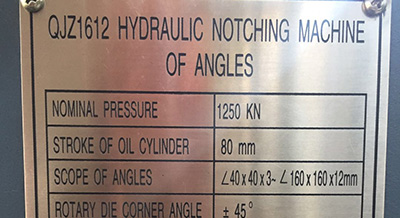

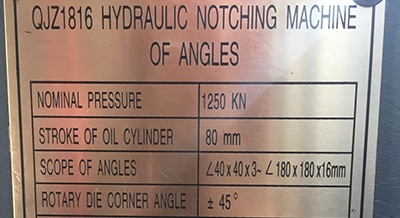

| Model | QJZ1612 | QJZ1816 | QJZ2020 |

|---|---|---|---|

| Functions | Angle notching in steel tower industry, also used for marking & punching if replace mould. | ||

| Nominal pressure (KN) | 1000 | 1250 | 1800 |

| Stroke of oil cylinder | 80 | 80 | 80 |

| Times of stroke | 20~25 | 20~25 | 20~25 |

| Motor power (KW) | 15 | 15 | 22 |

| Angle size (mm) | L40x40x3~140x140x12 | L40x40x3~180x180x16 | L40x40x3~200x200x20 |

| Bending thickness (mm) | 6-12 | 6-12 | 6-16 |

| Bending length(mm) | 600 | 600 | 600 |

| Rotation angle of mold | ±45° manual | ||

| Notching mould dimensions (mm) | 650x650x500 | 800x700x500 | 830x700x600 |

| Overall dimension(L×W×H)(mm) | 2000x1020x1800 | 2180x1020x1800 | 2260x1120x1900 |