High Speed CNC Tube Drilling Machine GT

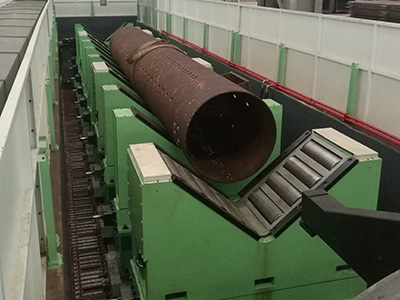

Machine application:

Machine is mainly used in boiler industry for processing boiler drum and tube sheet,uses special carbide drill for drilling holes and welding groove; Adopts BT50 precision spindle, can realize high speed processing; CAD/CAM direct conversion, automation and high precision processing, supports ERP system. Multi gantry structure can be designed by customer’s requirement.

Machine configuration:

High speed CNC tube drilling machine is mainly composed of frame, supporting bracket, slide table, drilling head, hydraulic station, clamping device, chip conveyor, cooling system, electrical system, hydraulic system, laser lineation device.

Machine features:

1.Adopts famous brand imported spindles, with super large torque output capability, spindle adopts synchronous pulley type.

2.Electrical system: Machine adopts Germany SIEMENS 840D or 2 sets of 828D CNC system, with RS232 interface and LCD, CAD/CAM coordinate conversion can be achieved directly, with preview and review functions before drilling, very easy operation.

3.Boiler drum supporting bracket, lifting supporting bracket and fixed supporting bracket 2 types, lifting supporting bracket lifts workpiece when rotates, and lower to fixed supporting bracket to prevent from workpice slipping.

4.Independent drive of each gantry, gantry numbers can be designed by customer’s requirement;

5.Spindle box adopts resin sand formed cast iron with high strength and reinforcement structure, good rigidity and stability.

6.CNC dividing head is fixed on one end of machine base. Adopts precision slewing bearing, realizes CNC indexing through servo motor via precision planetary reducer. Dividing head is equipped with 3 jaw self centering chuck, convenient for clamping and unloading workpiece, reduces labor force.

Parameters:

| Name | Item | Values |

|---|---|---|

| Workpiece size | Outer diameter range | φ200-φ1700mm(by requirement) |

| Max.workpiece thickness | 10-200mm | |

| Max. length | 15m(by requirement) | |

| CNC dividing head (A axis) | Indexing rotary speed (CNC) | 0~2.8r/min |

| Indexing accuracy | ±3 | |

| Indexing servo motor power | 10kW | |

| Drilling head and vertical sliding table (Z axis) | Max.drilling diameter | φ80mm |

| Max.diameter of trepanning | φ280mm | |

| Spindle rotation speed (Servo) | 30~3000r/min | |

| Max. torque of spindle | 700Nm | |

| Spindle motor power | 37kW | |

| Vertical sliding table stroke (Z axis) | 800mm/1200mm | |

| Z axis feeding speed | 0~5m/min | |

| Z axis servo motor power | 5.2kW | |

| Gantry (X axis) | X axis Max. stroke | 15m |

| X axis Max. moving speed | 10m/min | |

| X axis servo motor power | 2x5.2kW | |

| X axis positioning accuracy | 0.15mm/full length | |

| Clamping cylinder (up clamping) | Quanlity | 2 |

| Clamping pressure | 4-16kN | |

| Tube supporting bracket | Quanlity | 10 |

| Single support force | 70kN | |

| Hydraulic system | Hydraulic pump pressure/flow | 3~7MPa/15L/min |

| Hydraulic pump motor power | 3.0kW | |

| Compressed air supply pressure | 0.5MPa | |

| Chip conveyor and cooling | Type of chip-conveyor | Plate chain type |

| Chip-conveyor motor power | 2.2kW | |

| Cooling pump motor power | 0.45kW | |

| Electrical system | CNC system | SIEMENS 828D |

| CNC axis | 4+1 spindle | |

| Total motor power | About 70kW | |

| Overall dimension(LxWxH) | About 22x5.7x4.5m | |

| Net weight | About 150t |