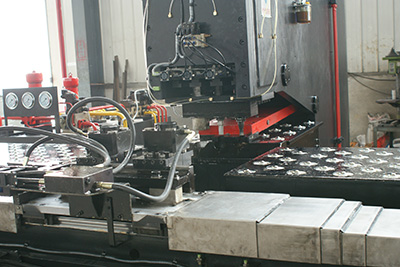

CNC plate punching machine CJ110

Machine application:

Hydraulic plate punching machine is high efficiency and accuracy equipment for steel plate processing, widely applied in steel tower, power transmission, or other industries using connection plates, machine realizes plate punching and marking functions.

Machine features:

1.Programming software is powerful, easy to learn, programming, nesting, real time display of programming, and check the procedures.

2.PLC adopts Japan MITSUBISHI.

3.X, Y axis adopt Japan YASKAWA advanced servo motor, ensures positioning accuracy and maintenance free, A, B axis max. positioning speed is 12m/min, no-load position accuracy is ±0.1mm.

4.With complete breakdown alarm system, can point out breakdown position and reasons.

5.Program can correct irregular workpice size.

6.Control system can directly converts lofting software or AUTOCAD program.

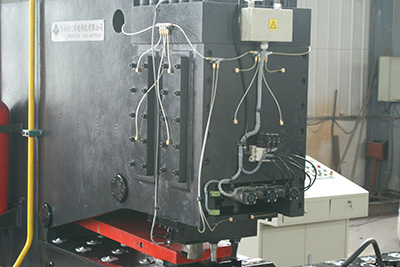

7.Main cylinder is integral structure, solves screw breakage and other problems, machine is more reliable for usage.

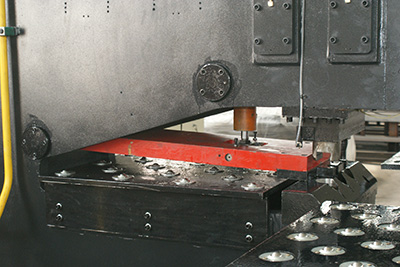

8.Press rod adopts hinge shaft structure with high structural strength, hydraulic cylinder provides pressure, big pressure and stable pressing.

Machine advantages:

1.Movable cylinder and fixed piston structure, punching force up to 110t, side plate, guide holder, plunger rod are reinforced, mechanical rigidity is greatly improved, ensures long term stable operation.

2.Piston rod with a fixed point spherical connection, automatic adjustment of offset load force, protects piston rod and the stress surface.

3.8 copper plates as slide guide around cylinder, the fit clearance is accurately controlled during the assembly process, so that the guide surface is increased and reliable, reduces eccentric load of the internal seal of the cylinder during the punching process, more stable operation, improves cylinder and seals longevity. Machine has perfect performance to process steel plates over 16mm in thickness.

Parameters list:

| No. | Item | Unit | Values |

|---|---|---|---|

| 1 | Max.workpiece size | mm | 1500×1000(can enlarge processing range of X axis through re-positioning) |

| 2 | Workpiece thickness | mm | 5~25 |

| 3 | Max. punching diameter | mm | Φ26 (σb≤410MPa) |

| 4 | Moulds numbers | pcs | 3 |

| 5 | Min. Distance from hole center to plate edge | mm | 25 |

| 6 | Punching force | KN | 1100 |

| 7 | Marking force | KN | 1000 |

| 8 | Letter size | mm | 14×10×19 |

| 9 | Letter numbers | pc | 14 or 18 (2 or 3 rows) |

| 10 | Hydraulic block stroke | mm | 50 |

| 11 | CNC axis | number | 2 |

| 12 | Servo motor power | kW | 2×1.8 |

| 13 | Hydraulic pump motor power | kW | 15 |

| 14 | Total power | kW | 20 |

| 15 | Overall size | mm | 3756×3228×2866 |

| 16 | Max.workpiece weight | t | 4.5 |

| 17 | Net weight | kg | 10400 |

| 18 | Processing accuracy | GB2694-2003 |