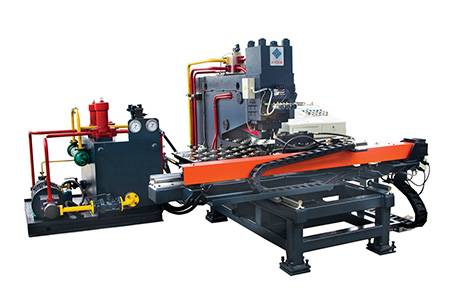

CNC plate punching machine CJ100

Machine application:

Hydraulic plate punching machine is high efficiency and accuracy equipment for steel plate processing, widely applied in steel tower, power transmission, or other industries using connection plates, machine realizes plate punching and marking functions.

Machine features:

1.CJ100 is C frame structure, welded from high strength plates, after optimal design, stress position is greatly strengthened, good rigidity and processing stability.

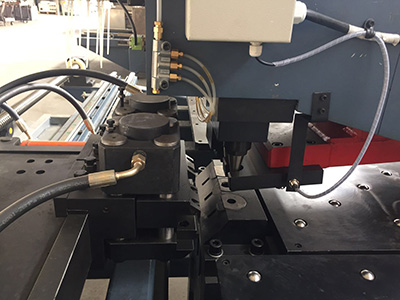

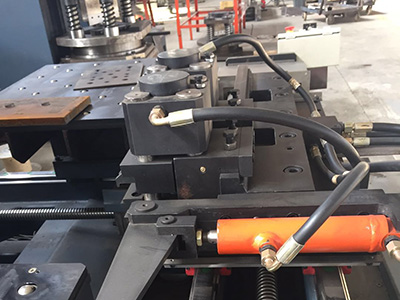

2.Two punching units with one marking unit, easy to change mould according to processing needs.

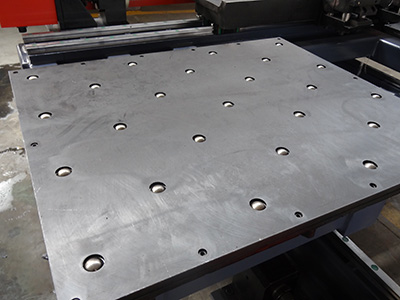

3.Roller supporting table, sliding resistance is small, convenient to use.

4.Two clamps can float, adopts hydraulic cylinder for driving, the clamp uses the decompression branch to supply oil, clamping force is not influenced by punching force.

5.X and Y axis adopts CNC system, ensures positioning accuracy. Driven by servo motor and precision ball screw, stable running and processing.

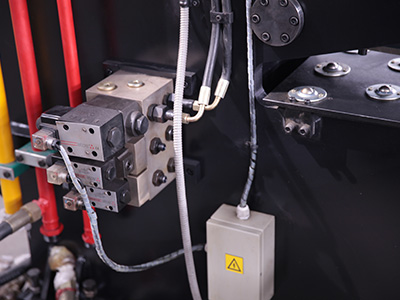

6.Hydraulic system low heat, small vibration noise; With oil level and oil temperature alarm.

7.Work piece program can be input manually, also can be created by lofting software automatically and then transmitted through USB or network, stimulant work piece graphics can be displayed in order to make program checking more conveniently.

Parameters list:

| No. | Item | Unit | Values | |

|---|---|---|---|---|

| 1 | Workpiece thickness | mm | 5—25 | |

| 2 | Max.workpiece size | mm | 1500x800 | |

| 3 | Punching force | KN | 1000 | |

| 4 | Max. punching diameter | mm | 26 (σb≤410MPa) | |

| 5 | Punching diameter x thickness | Q235 σ≤420Mpa | mm×mm | 26x25 |

| 16Mn σ≤610Mpa | mm×mm | 26x20 | ||

| 6 | Marking force | KN | 800 | |

| 7 | Letter size | mm x mm | 14x10x19 | |

| 8 | Letter numbers in one group | pcs | 14 or 18 (2 or 3 rows) | |

| 9 | Oil pump motor power | KW | 15 | |

| 10 | X axis servo motor | KW | 1.8 | |

| 11 | Y axis servo motor | KW | 1.8 | |

| 12 | High pressure working pressure | Mpa | 25 | |

| 13 | Low pressure working pressure | Mpa | 5.5 | |

| 14 | Oil tank capacity | L | 680 | |

| 15 | Cooling method | — | Oil to-water heat exchanger | |

| 16 | Pneumatic system max. working pressure | Mpa | 0.6 | |

| 17 | Pneumatic system min. working pressure | Mpa | 0.5 | |

| 18 | Processing accuracy | GB/T 2694-2003 | ||

| 19 | Overall size | mm | 3020×2522×1875 | |

| 20 | Net weight | kg | 5500 | |

| 21 | Data interface | Can input through keyboard, U disk, connect with lofting software. | ||