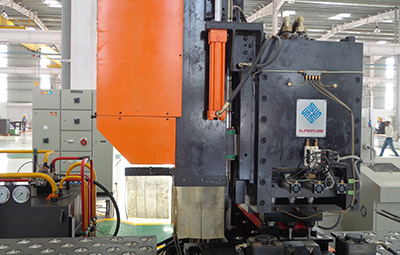

CNC Hydraulic Plate Punching, Drilling, Marking Machine CJHZ110

Machine application:

The stronger CNC Hydraulic Marking and Punching or Drilling Machine Piston fixed, cylinder movement, four-oriented, eight-oriented band, smooth motion, long-term stability of the working pressure to reduce the punching power during the partial load, the device greatly improves stability and reliability. For long time usage, this machine can keep high precision.

Machine features:

1. Workpiece program can be input manually, also can be created by lofting software automatically and then transmitted through USB or network, stimulant workpiece graphics can be displayed in order to make program checking more conveniently.

2. Manufacturing process can be monitored in real-time, including data of process, status of external switches, and the indication of malfunction diagnosing is perfect.

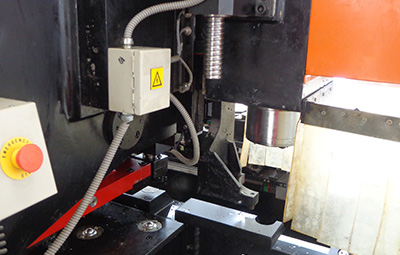

3. We provide an optional drilling unit, can compose a complex punching and drilling machine, the rotate speed of spindle and in feeding speed can be stepless adjusted.

4. As touching the workpiece, infeed speed changes from fast speed to working speed automatically. As drilling through workpiece, spindle returns rapidly, the maximum diameter can be processed up to 50mm.

5. Self-correcting hydraulic clamp. Automatically adapts to the inequalities of workpiece, distance between two clamps can be adjusted to adapt to workpiece size. High-powered hydraulic system, system maintenance is convenient.

Parameters:

| Model | CJHZ110 | |

|---|---|---|

| Punching force(kN) | 1100 | |

| Marking force(kN) | 800 | |

| Workpiece thickness (mm) | 5-25(for Punching) | 35(for Drilling) |

| Max. workpiece dimension (mm) | 1500×1000 | |

| Number of stations | 4 | |

| Max. punching dia. (mm) | Φ26 | |

| Max. drilling dia. (mm) | Φ40 | |

| Spindle taper | BT40 | |

| Min. margin distance from a hole center (mm) | 25 (Punching) | |

| Up to diameter while drilling | ||

| Stroke of hydraulic slide (mm) | 50 | |

| Air pressure (MPa) | 0.5 | |

| Letter size (mm) | 16×10 (custom-designed) | |

| Hydraulic pump motor power (kW) | 15 | |

| Servo motor power (kW) | 2×2 | |

| Spindle stroke (mm) | 300 | |

| Spindle drilling speed (stepless adjustment, rpm) | 50-3000 | |

| Working precision | According to standard GB/T2694-2003 | |

| Net weight (kg) | 7000 | |

| Overall dimension (L×W×H) mm | 3020×3420×2722 | |