CNC High Speed Plate Drilling Machine GZC

Machine application:

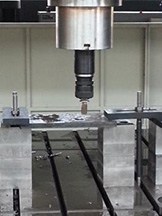

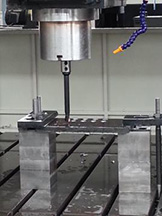

Gantry movable CNC drilling & milling machine, with function of drilling, rigid tapping and milling, can clamp carbide drill inner-cooling or high-speed metal twist drill outer cooling. Mainly used in the processing of flange, heat-exchanger, tube sheet. With high efficiency, precision, easy programming and operation.

This machine as flexible CNC drilling machine, can be adapt to mass production of various work pieces.

Machine configuration:

This equipment is composed of main bed and longitudinal sliding stable gantry, transverse sliding table, the vertical ram drilling power head, working table, auxiliary working table, three jaw hydraulic chuck, chip conveyor, hydraulic system, cooling system, centralized lubrication system, electrical system, pneumatic system etc.

Machine features:

1. This machine is gantry movable drilling machine, reduces bed length and saves space. The lathe bed is steel plate welded, through the weld artificial aging treatment, ensures the stability and accuracy of machine. Reinforced gantry makes rigidity greatly improved, can ensure large cutting parameters. Worktable is equipped with a number of transverse T-slot to clamp the clamping tools and work pieces.

2. Spindle is inner cooling precision BT50, rotation speed is 30-3000r/min.

3. With electrical manual pulse generator, setting the feeding position when drilling the first hole, which will speed up the whole procedure of feeding-drilling-back for same diameter hole. It will save much time, improve production efficiency. Besides, it has the following functions: chip breaking, chip removing, pause, protection of broken drill.

4. With optical edge finder, easy to find workpiece position.

5. SIEMENS 808D CNC system, with RS232 interface and LCD monitor, can fulfill CAD/CAM direct conversion, facilitates programming, restoring, displaying and communication. Operation interface has the functions of man-machine interaction, compensation, automatic alarm. With the function of hole position previewing and re-checking before drilling, very easy operation.

6. Machine components, such as ball screw, linear rolling guide, hydraulic pump, valve, servo motor are world famous brands products.

Parameters list:

| Name | Item | GZC2020 | GZC2525 | GZC3030 |

|---|---|---|---|---|

| Max.workpiece size | L X W | 2000X2000mm | 2500X2500mm | 3000X3000mm |

| Max.workpiece thickness | 300mm | 300mm | 300mm | |

| Worktable | T-slot width | 28mm | 28mm | 28mm |

| Vertical ram type Drilling head | Quantity | 1 | 1 | 1 |

| Spindle typer | BT50 | BT50 | BT50 | |

| Max. drilling dia. | Φ60mm | Φ60mm | Φ60mm | |

| Drilling depth | ≤300 | ≤300 | ≤300 | |

| Spindle rotation speed | 30—3000r/min | 30—3000r/min | 30—3000r/min | |

| Spindle motor power | 37/56kW | 37/56kW | 37/56kW | |

| Spindle max.torque | 700Nm | 700Nm | 700Nm | |

| Distance between spindle end and worktable | 280-780mm | 280-780mm | 280-780mm | |

| Gantry longitudinal movement (x axis) X-axis | Max. stroke | 2000mm | 2500mm | 3000mm |

| X-axis moving speed | 0-10m/min | 0-10m/min | 0-10m/min | |

| X-axis servo motor power/torque | 2X3.5kW/28.4Nm | 2X3.5kW/28.4Nm | 2X3.5kW/28.4Nm | |

| Transverse movement of drilling head (Y axis) | Y-axis Max. stroke | 2000mm | 2500mm | 3000mm |

| Y-axis moving speed | 0-10m/min | 0-10m/min | 0-10m/min | |

| Y-axis servo motor power/torque | 3.5kW/28.4Nm | 3.5kW/28.4Nm | 3.5kW/28.4Nm | |

| Feeding of drilling head (Z axis) | Y-axis Max. stroke | 500mm | 500mm | 500mm |

| Y-axis feeding speed | 0-5m/min | 0-5m/min | 0-5m/min | |

| Y-axis servo motor power/torque | 3.5kW/28.4Nm | 3.5kW/28.4Nm | 3.5kW/28.4Nm | |

| Positioning accuracy | X axis | 0.06mm/full length | 0.06mm/full length | 0.06mm/full length |

| Y axis | 0.06mm/full length | 0.06mm/full length | 0.06mm/full length | |

| Re-positioning accuracy | X axis | 0.03mm | 0.03mm | 0.03mm |

| Y axis | 0.03mm | 0.03mm | 0.03mm | |

| Hydraulic system | Hydraulic pump pressure/flow | 6.5MPa/25L/min | 6.5MPa/25L/min | 6.5MPa/25L/min |

| Hydraulic pump motor power | 3kW | 3kW | 3kW | |

| Pneumatic system | Compressed air pressure | ≥0.4MPa | ≥0.4MPa | ≥0.4MPa |

| Chip removal and cooling | Chip conveyor type | Plate chain | Plate chain | Plate chain |

| Chip conveyor quantity | 1 | 1 | 1 | |

| Chip removal speed | 1m/min | 1m/min | 1m/min | |

| Chip conveyor motor power | 0.75kW | 0.75kW | 0.75kW | |

| Inner cooling motor power | 3kW | 3kW | 3kW | |

| Out cooling motor power | 0.75kW | 0.75kW | 0.75kW | |

| Automatic lubrication system | Lubrication pressure | 2MPa | 2MPa | 2MPa |

| Oiling point | 0.1mL | 0.1mL | 0.1mL | |

| Lubrication cycle | 6-10min | 6-10min | 6-10min | |

| Electrical system | CNC system | SIEMENS 808D | SIEMENS 808D | SIEMENS 808D |

| CNC axis | 4 | 4 | 4 | |

| Total power | 65kW | 65kW | 65kW | |

| Overall size | L x W x H/m | 6.2X5.3X3.6 | 7.1X6.0X3.6 | 7.5X6.4X3.6 |

| Net weight | 25t |