H beam beveling machine SXA1250/6

Machine application:

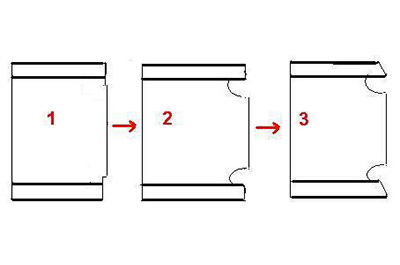

Machine is mainly used in construction, bridge, municipal steel structure H beam milling groove, end face and web milling groove.

Machine features:

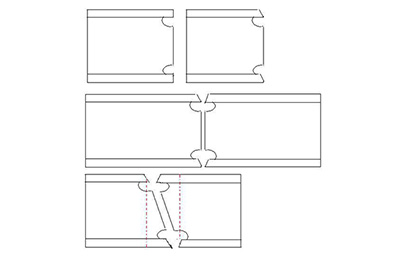

1.One time finishes H beam beveling by adopting CNC slide table.

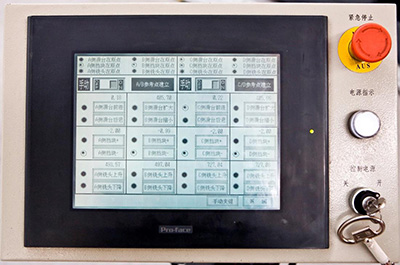

2.Machine has automatic setting of cutting parameter, improves efficiency.

3.Frequency conversion roller table ensures stable feeding.

4.Can adjust cone milling cutter parameter according to milling head depth, groove count and gets the groove parameter.

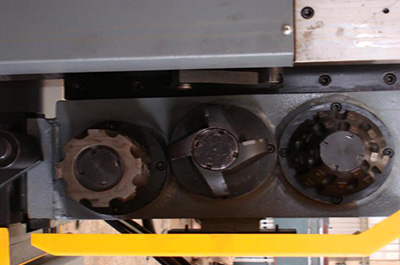

5.Uses carbide indexable face-milling cutter.

6.International famous brands components, display of processing parameters, high positioning accuracy, prolongs machine service time.

Parameter list:

| Items | Names | Values |

|---|---|---|

| H beam size | Width | 220-1250mm |

| Height | 100-600mm | |

| Web thickness | 10-55mm | |

| Section inclination | ≤300mm | |

| Length | ≥400mm | |

| Milling head | Quantity | 2 |

| Spindle rotation speed | 400r/min | |

| Main motor power | 2x15kW | |

| Slide table | Longitudinal slide table stroke | 300mm |

| Transverse slide table stroke | 1050mm | |

| Slide table move speed | 150-1000mm/min | |

| Slide table motor power | 2x0.37kW | |

| Milling pillar | Quantity | 2 |

| Drilling head vertical move stroke | 1300mm | |

| Vertical move drive motor | 2x2.2kW | |

| Clamp move range | 100-600mm | |

| Clamp mode | Hydraulic clamp | |

| Automatic deep milling block | Quantity | 2 |

| Adjustment amount | 0-+40mm | |

| Motor power | 2x0.06kW | |

| Inner and outer roller | Out feeding conveyor length | 5000mm |

| Feeding speed(stepless adjustment) | 2.5-20m/min | |

| Out feeding motor power | 1x0.55kW | |

| Overall size | 7.0×4.0×2.8 m | |

| Net weight | 11t |