Angle Heel Milling Machine CB25

A. Product Usage:

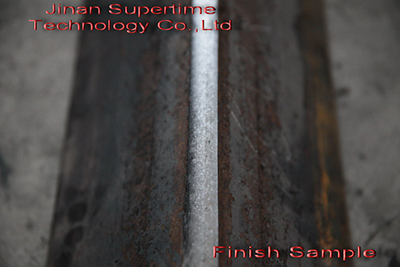

Angle steel tower structure, extensive use of the coated iron fittings, in order to close the connection, must heel milling of the connecting iron. At present, most of the steel tower company use planer for processing, this processing method cause labor intensity and low efficiency.

With electric power industry development, manufacturing level of the power tower calls for higher requirements, planer processing method can’t meet production demands. Jinan Supertime Technology Co.,Ltd designs and manufactures CB angel heel milling machine, adopts high speed milling principle, is an essential equipment in steel tower production.

B. Product Feature:

1. Greatly increases production efficiency in comparison with traditional planer processing,production efficiency is 10 times compared with the planer;

2. Reduces requirements for operating level of workers, easy operation;

3. Reduces labor force and high degree of mechanical automation;

4. Angle length processing can be controlled automatically by program;

5. Compared with planer, overcomes the processing length limitation, this machine hasn’t length limitation, more flexible and convenient for production processing.

6. Convenient for operation, flexible pressure adjustment and stable operation;

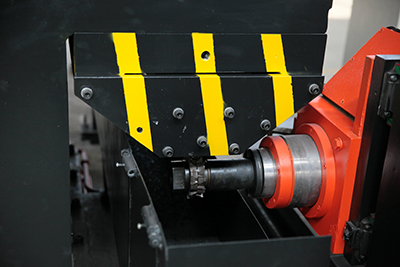

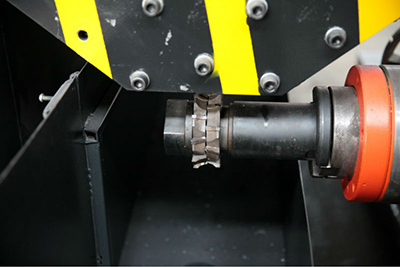

7. Movable tool and fixed workpiece, stable milling, prolongs tool longevity, reduces use cost and breakdown rate;

CB25 technical parameters:

| Name | Unit | Values |

|---|---|---|

| Angle size | mm | 63×63×5-250x250x25 |

| Max.length of one time processing | mm | 1200 |

| Power head feeding speed | mm/min | 100-300 |

| Cutter head max.diameter | mm | 105 |

| Angle clamping method | Hydraulic automatic clamping | |

| Milling knife height adjustment (heel depth adjustment) | manual | |

| Power head rotation speed | r/min (6 gears) | 75, 105, 150, 210, 300, 420 |

| Overall size (L x W x H) | m | 3.5x1.8x2 |

| Net weight | kg | 4000 |

CB25 Angle heel milling machine advantages:

1. Adopts hydraulic clamping method, reliable fixation during processing, prolongs tool longevity and more stable processing.

2. Free control of machining length of workpiece, workpiece fixed type with advantages of processing any length rather than full length heel milling.

3. Machine is stable and reliable, long service time, low breakdown rate.