Five major factors affecting CNC tools 2

- 28 January 2019

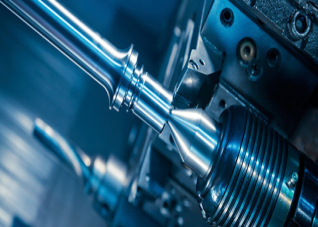

- CNC Tools

2, the geometric angle of the tool

The choice of the appropriate geometric angle of the graphite tool helps to reduce the vibration of the tool, and in turn, the graphite workpiece is not easily broken;

(1) The rake angle, when the graphite is processed by the negative rake angle, the cutting edge strength is good, and the impact resistance and friction performance are good. As the absolute value of the negative rake angle decreases, the flank wear area does not change much, but The overall trend is decreasing. When the positive rake angle is used, the tool edge strength is weakened as the rake angle increases, which in turn leads to increased wear on the flank. When the negative rake angle is processed, the cutting resistance is large, and the cutting vibration is increased. When the large positive rake angle is used, the tool wear is severe and the cutting vibration is large.

(2) Back angle, if the back angle increases, the tool edge strength decreases, and the flank wear area gradually increases. When the back angle of the tool is too large, the cutting vibration is strengthened.

Mark

info@jntime.com

Tel/Whatsapp: +86 15863147078