Choosing Materials 1

- 15 October 2018

- Choosing Materials

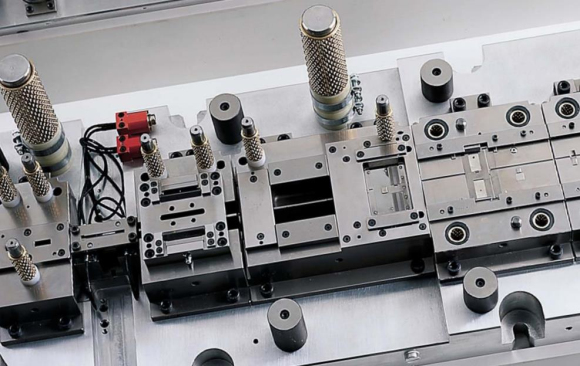

As a result of rising cost pressure, it is inevitable to pay more attention than before on costs. In accordance with tool making, this shows that requirements are growing all the time in respect of material selection, as well as heat and surface treatment.

Selecting economical steel does not in any way include applying the most inexpensive steel. It is way more significant to choose the best material for the planned purpose. If the inappropriate material has been selected, this often only happens when the tool is used in operation, possibly ended in remarkable extra costs.

When choosing a tool steel, it is considerable to have in mind that the tool must not occur any problem in time of use or chip around the cutting lip. Equally, constant deformation and immature changes to the tool surface as a result of abrasion wear or erosion need to be eliminated. Steel practicality should also be inspected. Because of the cost case, steel manufacturers are being compelled to bound their product spectrum. In these years, however, various highly universal tool steels have been exploited, which empower tool steel portfolios to be confined without concessiving on technical properties. This basically has important benefits for toolmakers.

Mark

info@jntime.com

Tel/Whatsapp: +86 15863147078