About milling machines tools two

- 18 February 2019

- CNC Tools

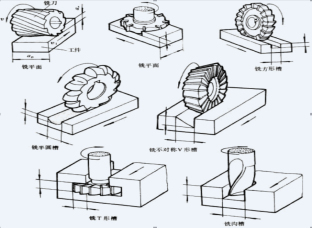

As a result, the axis of milling cutter parallel to the workpiece machining surface milling generally divided by milling and end milling two ways. Peripheral milling is the milling of the cutter teeth on the circumference of the cutter body, with the peripheral cutting edge. End milling is the milling of the cutter teeth on the end face of the cutter body. Both the peripheral edge and the end face edge play a cutting role at the same time. The axis of the milling cutter is perpendicular to a machining surface. The end milling and some asymmetrical milling also have reverse milling and down milling. Where the cutting direction of the blade is opposite to that of the workpiece feed motion, it is called reverse milling. The same direction is known as milling along. During the reverse milling, the cutting thickness of each tooth of the milling cutter increases gradually from zero, so when the cutter starts cutting, it will be extruded and rubbed against the cutting surface, which has adverse effects on the life of the milling cutter and the surface quality of the milling workpiece. The situation is opposite when milling, so milling forward can improve the milling cutter life and milling surface quality, and reduce the power consumption of the machine. But the cutting force of the milling cutter is greater when milling along the mill, when the feed drive mechanism of the machine tool has clearance or casting and forging blank has hard skin, it is not appropriate to use down milling to avoid vibration and damage of the cutter.

As a kind of multi-tooth cutter, the total length of the cutting edge involved in cutting is relatively long, and it can be used with a higher cutting speed and no free travel. Therefore, in general, the productivity of milling is higher than that of the cutting process (such as planing and slotting) of the single-edge cutter. However, the manufacturing and cutting edge grinding of the milling cutter are more difficult.

General milling precision is not high, general rough milling precision is IT11 ~ 10, surface roughness is Ra20 ~ 2.5 micron; Precision milling can reach IT9 ~ 7, surface roughness is Ra2.5 ~ 0.16 micron.

Mark

info@jntime.com

Tel/Whatsapp: +86 15863147078