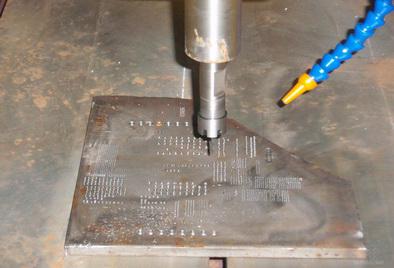

How to choose CNC plate drilling machine model

Here we give you suggestions how to choose CNC plate drilling machine model according to different industries.

1) Steel structure, steel tower plate processing:

a. Normal speed (to 560rpm): CJZ series.

b. High speed economical type (to 3000rpm):

CJHZA series, JNYO spindle, max.drilling diameter 50mm.

CJHZB series. JNYO spindle, max.drilling diameter 40mm.

c. High speed type (6000rpm):

KENTURN spindle BT40, max. drilling diameter 40mm, with ATC (for selection), has drilling, tapping, milling functions etc.

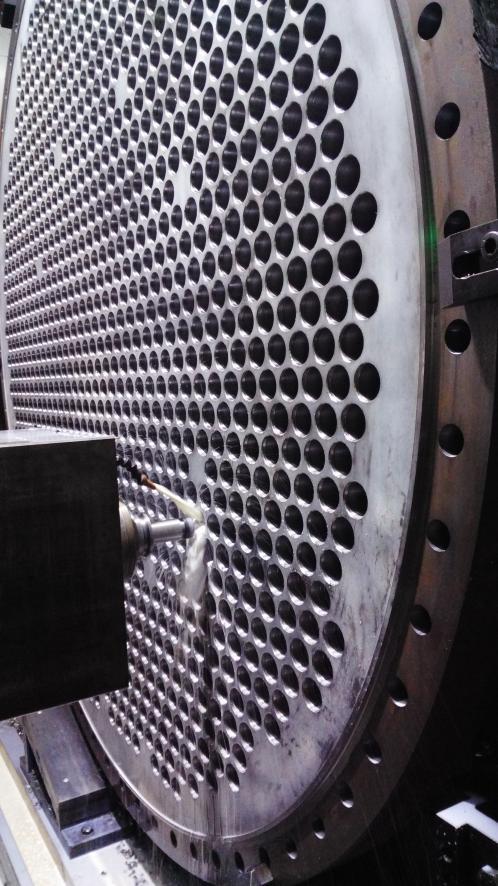

2) Petrochemical industry tube sheet processing:

Large quantity of holes, diameter 10-30mm, thickness 100-300mm. Sometimes need milling groove on tube sheet.

a. GZP series: worktable and machine frame are separated, better absorbs vibration force during high speed processing. BT50 spindle, Max. drilling diameter 90mm.

b. GZC series: BT50 spindle, Max. drilling diameter 90mm.

c. CJHZ series: BT40 spindle. Max.drilling diameter 40mm.

3) Nuclear Heat exchanger, Tube plate processing:

WZ series CNC horizontal drilling machine is suitable. Because this machine structure can ensure better chip removal effect.

4) Boiler industry Tube plate processing:

Before boiler industry adopted coal burning, max. hole diameter for tube plate is 50mm. Nowadays, gas boiler is more popular, max. hole diameter is 76mm.

GZP or GZC series: high speed drilling type.

DZC series: normal speed drilling type.

5) Paper making, pharmaceutical industry plate processing:

Large quantity of holes, and large density, relatively small diameter. A high efficiency processing equipment is required.

CJSZ series: for pulp or particulate filtration. Spindle rotation speed to 4000rpm.