Structure and working principle of CNC beam drilling sawing machine

Supertime is a professional manufacturer of beam processing machines. Including CNC beam drilling machine, CNC band saw, beam beveling machine etc.

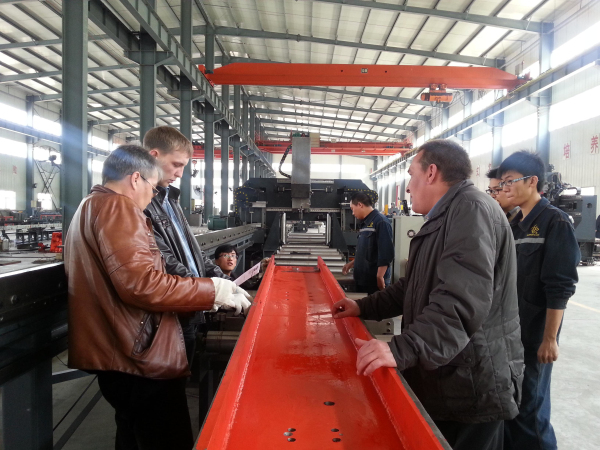

CNC beam drilling machine structure:

Feeding carriage, machine frame, CNC slide table, drilling heads, side pressing device, feeding conveyor, air-mist cooling, chip conveyor etc.

CNC beam drilling machine working principle:

1.For drilling H beam, channel, square tube, box girder, angle etc. Take GSWZ1250A/3 for example, adopts precision inner cooling BT40 spindle, can equip with carbide drill, with good rigidity and processing accuracy.

2.Hydraulic unclamping cylinder, easy to load and unload tools.

3.Spindle is driven by high power motor, rotation speed 30-3000rpm. Drilling holes on vertical and horizontal directions.

4.Input workpiece size, automatic generation of processing procedure.

CNC band saw structure:

Saw frame, machine frame, vertical feeding device, vertical pressing device, rotary worktable, hydraulic system, cooling system, carriage etc.

CNC band saw working principle:

Rotation angle band saw, rotation angle 0°-45°, workpiece fixed, rotary machine frame, realizes beam cutting in any degree. Excellent cutting and sawing performance, narrow saw blade, saves material; High efficiency and accuracy, easy operation; Real time display of processing parameters.