How to choose CNC angle punching machine model?

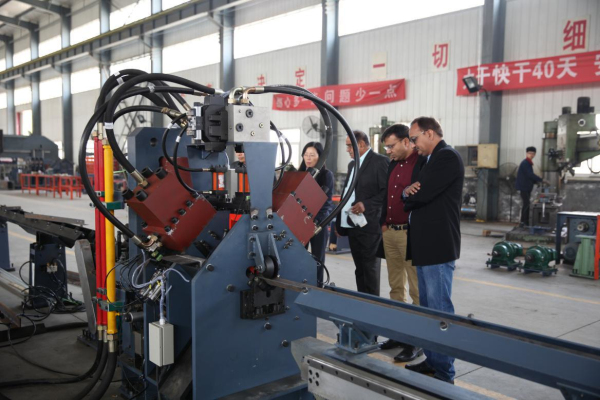

CNC angle punching, marking, shearing machine is widely applied in steel tower, power transmission and other industries.

Each country has own executive standard, steel angle norms are made according to standards. How to choose the right CNC angle punching machine model according to angle size?

Supertime offers complete CNC angle processing solutions.

CNC angle punching machines:

1.JX0808-Angle size 40x40x3-80x80x8mm.

2.JX1010-Angle size 40x40x3-100x100x10mm.

3.JX1412-Angle size 40x40x3-140x140x12mm.

4.JX2020-Angle size 63x63x4-200x200x20mm.

5.JX2020S-Stronger machine frame, with vertical pressing device, angle size 63x63x4-200x200x20mm.

CNC angle drilling machines:

When angle material Q235 thickness over 16mm, Q345 angle thickness over 14mm, Q420 angle thickness over 12mm, then we should adopt angle drilling instead of punching.

1.JX2532-Angle size 140x140x10-250x250x35mm. Drilling speed to 560rpm. 4 letter groups. 3 drilling heads on one side.

2.JX2532F-High speed angle drilling machine, angle size 140x140x10-250x250x35mm. BT40 spindle, drilling speed to 3000rpm. 4 letter groups. 3 drilling heads on one side.

3.JX3036-Angle size 140x140x10-300x300x36mm, drilling speed to 560rpm. 4 letter groups. 3 drilling heads on one side.

4.JX3540-Angle size 140x140x10-350x350x40mm. Drilling speed to 560rpm. 4 letter groups. 3 drilling heads on one side.

5.JX3540F-High speed angle drilling machine, angle size 140x140x10-350x350x40mm. BT40 spindle, drilling speed to 3000rpm. 4 letter groups. 3 drilling heads on one side.